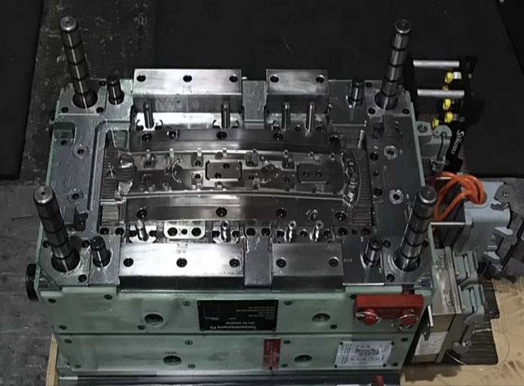

Custom Plastic Tooling

We have been in the plastic injection molding business for over 15 years and can help you make large, small, simple, complex molds.

From the confirmation of the mold drawing - the purchase of the front and rear mold core steel - the purchase of the mold blank - the deep hole drilling - the CNC roughing - the finishing - the electrode processing - the wire cutting processing - the spark machining and other processes, Strictly guarantee the size and quality of the product.

Special info.:

Following customers' requirement to make the molds.Mold base: LKM C50 standard mold molds Inserts(cavity and core): H13, 8407, 1.2344 or the material you required. Standard parts: HASCO, DME, MISUMI, Punch Lead time of first samples: Around 4~7weeks.

From the confirmation of the mold drawing - the purchase of the front and rear mold core steel - the purchase of the mold blank - the deep hole drilling - the CNC roughing - the finishing - the electrode processing - the wire cutting processing - the spark machining and other processes, Strictly guarantee the size and quality of the product.

Special info.:

Following customers' requirement to make the molds.Mold base: LKM C50 standard mold molds Inserts(cavity and core): H13, 8407, 1.2344 or the material you required. Standard parts: HASCO, DME, MISUMI, Punch Lead time of first samples: Around 4~7weeks.

-

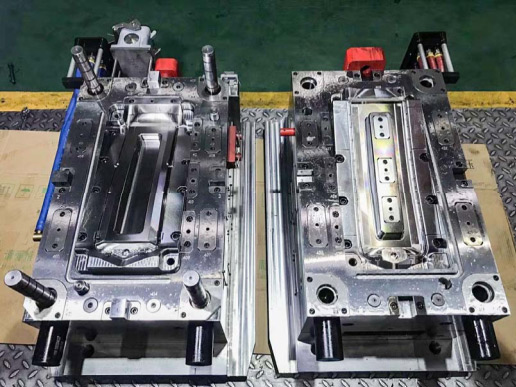

Smart home moldingMold Material:NAK80Tolerance:+/-0.05mm

Smart home moldingMold Material:NAK80Tolerance:+/-0.05mm -

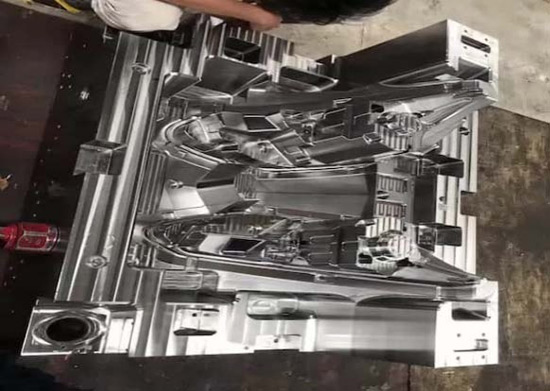

Auto interior parts moldMold Material:S136HTolerance:+/-0.005mm

Auto interior parts moldMold Material:S136HTolerance:+/-0.005mm -

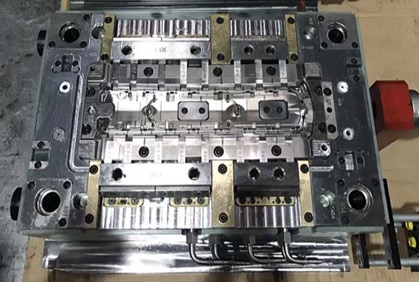

Plastic Tooling MakingMold Material:2316Tolerance:+/-0.05mm

Plastic Tooling MakingMold Material:2316Tolerance:+/-0.05mm -

OEM Plastic Product MoldsMold Material:P20HTolerance:+/-0.01mm

OEM Plastic Product MoldsMold Material:P20HTolerance:+/-0.01mm -

Precision MoldingMold Material:1.2344Tolerance:+/-0.01mm

Precision MoldingMold Material:1.2344Tolerance:+/-0.01mm -

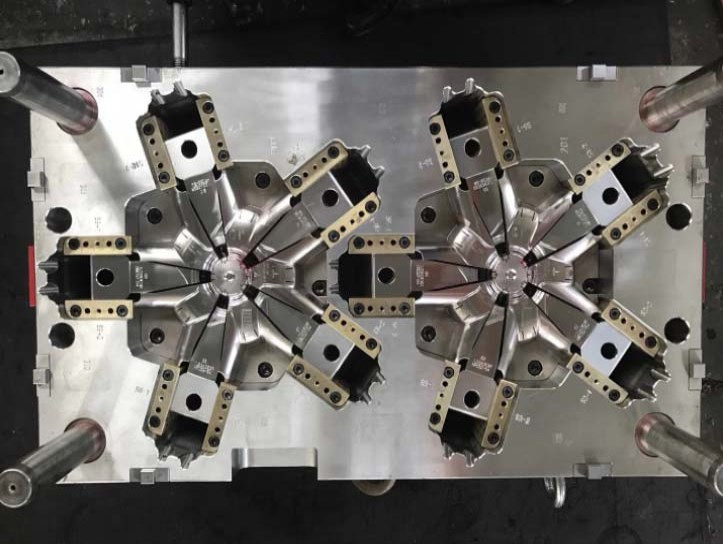

Multi cavity hot runner mouldMold Material:738HTolerance:+/-0.01mm

Multi cavity hot runner mouldMold Material:738HTolerance:+/-0.01mm -

Custom Precision MoldingMold Material:S136Tolerance:+/-0.005mm

Custom Precision MoldingMold Material:S136Tolerance:+/-0.005mm -

Plastic mold for electronic housingMold Material:NAK80Tolerance:+/-0.01mm

Plastic mold for electronic housingMold Material:NAK80Tolerance:+/-0.01mm -

Molds for auto partsMold Material:738HTolerance:+/-0.005mm

Molds for auto partsMold Material:738HTolerance:+/-0.005mm

- Total 1 Page 9 Records