Motor Vehicle Part

Brand Name:Hamsan

Mold Base:LKM;HASCO;DME,etc

Mold Material:738H

Tolerance:+/-0.05mm

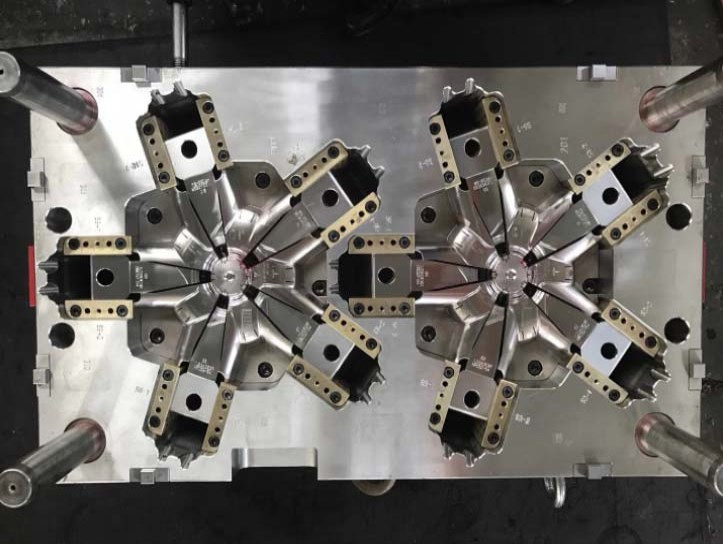

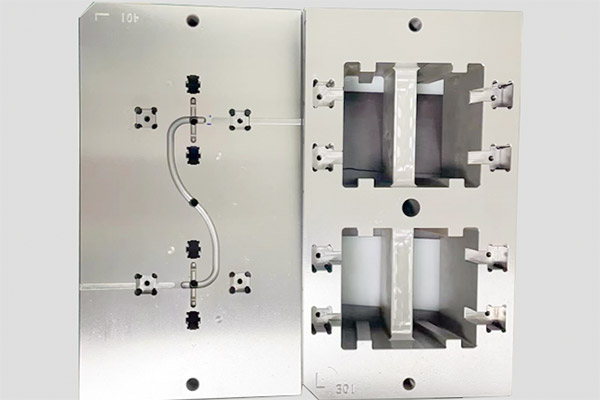

Shaping Mode:Plastic Injection Mold

Design Software:AutoCAD;NX;ProE

Packaging Details:Inner plastic bags+Wooden cases

Delivery Time:15-30 days

Products Details

Products Details

What is Plastic Injection Molding?Plastic injection molding involves melting granular plastic pellets into a liquid form and then compressing this liquid into the empty cavity of a mold tool. The plastic will retain the shape of the mold as well as the surface texture of the walls of the cavity. After an optimized injection and cooling phase, the now solidified plastic part is ejected and the molding cycle is repeated. This molding cycle can take from as little as a few seconds to several minutes depending on part size, molding resin, and part design.

Advantages of Plastic Injection Molding

1..We have thousands of different types of plastic available for you to choose from, for a wide range of mechanical and cosmetic properties.

2. Plastic injection molding makes more economic sense for larger volumes.

3. Hundreds of thousands of moldings can be produced from a single mold.

4. Your part can have excellent surface quality finishes in a wide range of polishes and textures.

5. Overmolding is available to combine different types of plastic in one piece.

6. It is ideal for lightweight parts that are immune to corrosion.

Are you ready to start your next project?

Once you send us your CAD file, our experts will review it to ensure manufacturability. When our engineers look at your design they will double-check draft angles, wall thickness, corner angles, material type, etc. Our engineers will also make sure the right materials are combined with the correct design considerations to ensure your next project meets and exceeds your expectations. Contact us to get your free quote.