Rapid Molding

Brand Name:Hamsan Tooling

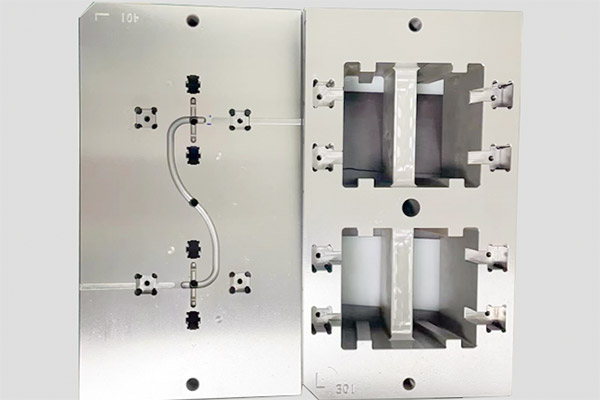

Mold Base:LKM;HASCO;DME,etc

Mold Material:Aluminum

Tolerance:+/-0.01mm

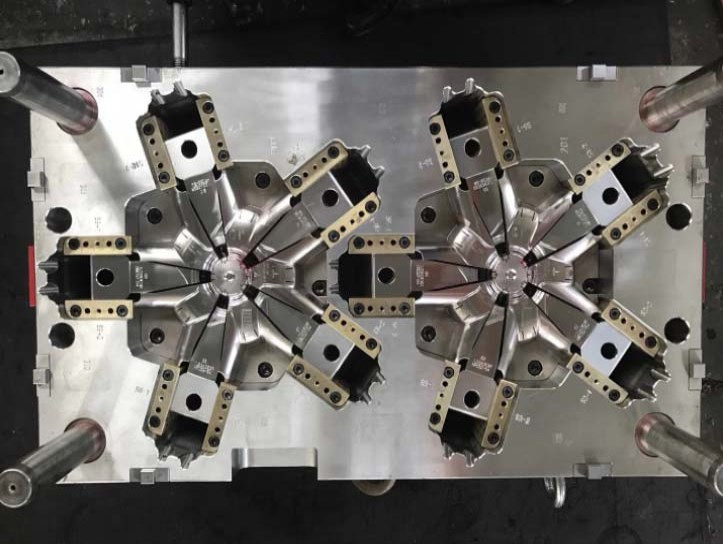

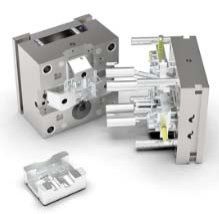

Shaping Mode:Plastic Injection Mould

Design Software:2D/(PDF/CAD)3D(IGES/STEP)

Packaging Details:Inner plastic bags+Wooden cases

Delivery Time:12-18 days manufacturing lead time

Products Details

What is rapid tooling?

Rapid Prototyping refers to any method or technology that enables rapid fabrication of a physical part that could be used as a prototype or end-use functional product. Common types of Rapid Prototyping technology are as follows:

(I) Additive Manufacturing (3D printing)

(II) Subtractive Manufacturing (CNC Machining)

Rapid tooling Compared to rapid prototyping, rapid tooling refers to any method or technique that enables the rapid production of parts that will act as tools (mainly molds). In manufacturing, one of the most common rapid tooling methods - injection molds are used as rapid tooling channels to mass produce your injection molded parts quickly and cheaply.

For entrepreneurs or small businesses looking to get their ideas on the market fast, Rapid Tooling and Rapid Prototyping are particularly the best and quickest ways for new product development in comparison to conventional manufacturing methods.

Benefits of Rapid Tooling:

1. Faster Time to Market

2. Lower Cost

3. Variety of Material Grades

4. Designs and Functionality Testing

5. Process Parameter Testing

Before starting your project, always consult with us about your requirement and expectation. The main factors that will decide whether the Rapid Tooling process is appropriate for your project are as follows:

Project Budget

Product Development Timeframe

Part Specification & Tolerances

Multiple Materials to be tested?

Mold or Die to be used for large-scale production?

What is the available lead time for opening a mold?

Rapid Tooling lead time range from 1-2 weeks.

Rapid Prototyping refers to any method or technology that enables rapid fabrication of a physical part that could be used as a prototype or end-use functional product. Common types of Rapid Prototyping technology are as follows:

(I) Additive Manufacturing (3D printing)

(II) Subtractive Manufacturing (CNC Machining)

Rapid tooling Compared to rapid prototyping, rapid tooling refers to any method or technique that enables the rapid production of parts that will act as tools (mainly molds). In manufacturing, one of the most common rapid tooling methods - injection molds are used as rapid tooling channels to mass produce your injection molded parts quickly and cheaply.

For entrepreneurs or small businesses looking to get their ideas on the market fast, Rapid Tooling and Rapid Prototyping are particularly the best and quickest ways for new product development in comparison to conventional manufacturing methods.

Benefits of Rapid Tooling:

1. Faster Time to Market

2. Lower Cost

3. Variety of Material Grades

4. Designs and Functionality Testing

5. Process Parameter Testing

Before starting your project, always consult with us about your requirement and expectation. The main factors that will decide whether the Rapid Tooling process is appropriate for your project are as follows:

Project Budget

Product Development Timeframe

Part Specification & Tolerances

Multiple Materials to be tested?

Mold or Die to be used for large-scale production?

What is the available lead time for opening a mold?

Rapid Tooling lead time range from 1-2 weeks.