Our Tooling Workshop

|

Our factory is located in the Shenzhen area, which covers about 5000 square meters and has a total workforce of 120. We have 8 designers, 4 project engineers, who have rich experience in their field and worked in the mold industry for many years. We already got ISO 9001:2018 certificates many years ago. With mold manufacturing and customized injection molding as our core competitiveness, we provide one-stop OEM services from design, procurement, assembly, long-term and short-term production, complex assembly, secondary processing (such as painting, printing, chrome plating, powder coating, etching, etc..), testing, packaging, and transportation. |

|

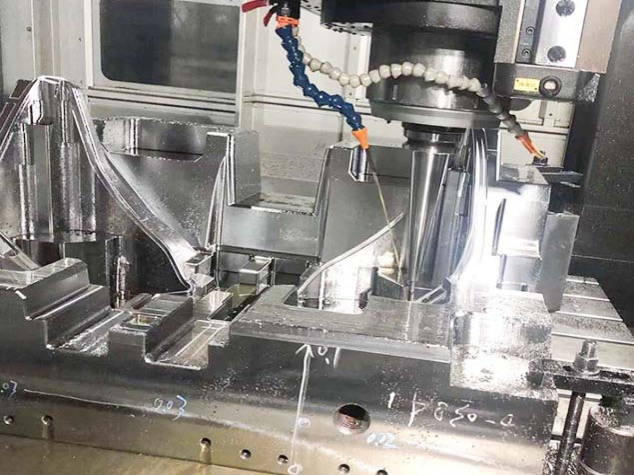

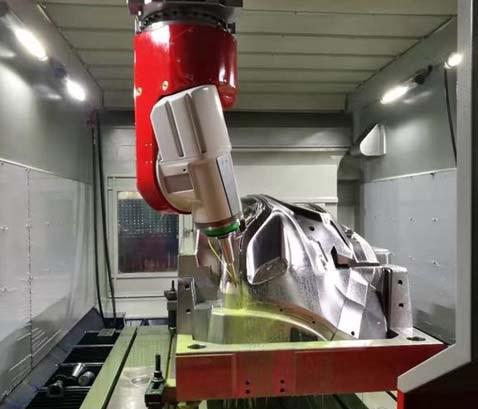

Precision CNC Machine Center

|

We are an international provider of high‐quality CNC machining services, CNC Milling and CNC Turning. We have sophisticated three‐axis, five‐axis, and turning‐milling compound equipment. Coupled with the latest technical support, we can manufacture high‐precision customized parts; we are good at cost control and processing of special‐shaped products, and can quickly deliver the parts required by customers. Precise cuts and a wide range of material options make CNC machining the preferred solution for prototyping and low‐volume manufacturing. |

Slow Feeding Wire Cut

|

The wire cut department is equipped with one set of Sodick WEDM machines. The general precision is 0.005mm. We also have a source for 5 sets of Seibu wire‐cut machines and 2 sets of Sodick oil wire‐cut machines. The wire cut precision can be within 0.001mm, the smallest wire used is 0.03mm and the smallest hole cut can be 0.12mm Sodick wire‐cut EDM Sodick wire‐cut EDM |

|

Mirror EDM Machine

|

Equipped with Sodick EDM machines imported from Japan, we are able to handle basic EDM precision is +/‐0.005mm and the highest precision can be within 0.003mm. EDM surface smoothness can be within 2um and corner clearance within R0.015mm if required. |

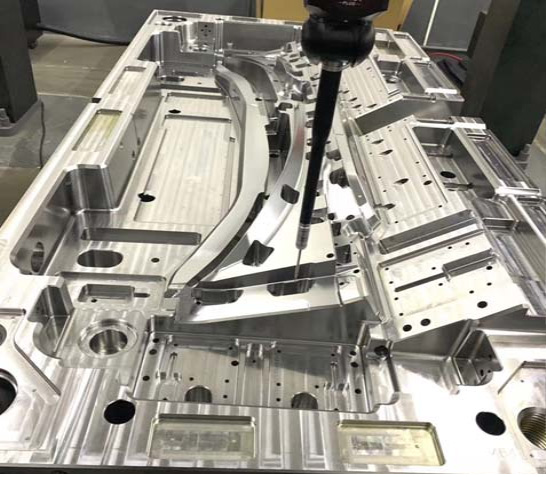

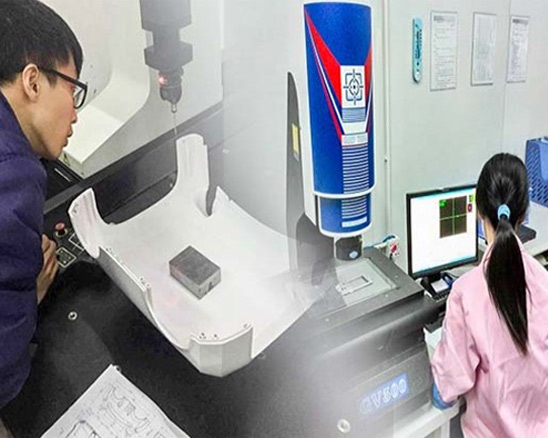

QC Department

Take quality as root, our products are inspected at every stage throughout the tooling process including drawing auditing, copper electrode, CNC, EDM, EDW, Fitting check before trialing the tooling, and pre‐shipment check, in addition, we can provide customers with FAI, GR&R, MSA, CPK and SPC reports. Strict quality management ensures the high quality of our products that meets or even exceed customers’ requirements. |

|

What Is Plastic Injection Molding?

|

Plastic injection molding involves melting plastic (in the form of pellets) into a malleable form and injecting the plastic under pressure into a mold, which forms the final product. The molds are often made of steel (hardened or pre‐hardened), aluminum, or beryllium‐copper alloy. Plastic injection molding is a highly‐ efficient process, allowing for large production runs of complex plastic parts to be produced fast in a cost‐effective manner. Molds used in injection molding are durable, lasting for over one million uses. Some of the plastics we design injection molds for include:

|

|

FTV & FQC Process / Delivery

|

FTV (Final Tool Validation) and FQC( Final Quality Checking ) Process to make sure all customers requirements are met and documented before tool shipment. |